We have had good luck placing these blocks by lowering them from a boat with a line and then using a lift bag to move it to the final desired position. By placing the block in a slightly protected location such as under an overhang of a larger boulder or wedged into an outcropping crack, they have lasted for many field seasons.

Materials needed:

- Deck Block

- 4” PVC Plain End Pipe (nominal diameter) (Table 8 Item 35)

- 4” PVC End Cap (nominal diameter)

- 5/16” thread x 4” length Stainless Steel

- Eye Bolt (or equivalent) (x2)

- 5/16” thread Concrete Anchor/Lag Shield (x2)

- 1/4” thread x 2.5” length Concrete Anchor Screws (x2)

- 1/4″ Stainless Steel Washer (x2)

Tools Needed:

- PVC Saw (or equivalent)

- 3/4” (1.9 cm) Concrete Drill Bit

- 3/16” (0.47625 cm) Concrete Drill Bit

- Hole Saw Arbor with 1/4” (0.635 cm) bit

- 2” (5.08 cm) Hole Saw

- 5/16” nut driver drill bit

- 1/2” (1.27 cm) general-purpose twist drill bit

3.1 Deck Block Modification

The top of the block must be cut to accept the 4” diameter pipe (Figure 40).

- Using the masonry blade on an angle grinder:

- Cut off approximately 1” (2.54 cm) from each side of one of the top channels (the overlap from the edge)

- The masonry blade we used was for a 4.5” grinder and makes a 2” deep cut)

- Use a cold chisel and hammer to break out the remaining piece of concrete

- Cut off approximately 1” (2.54 cm) from each side of one of the top channels (the overlap from the edge)

Now we will make the holes for the lag shields/concrete anchors

- Using the 3/4” (1.9 cm) masonry drill bit:

- Drill two 3/4” (1.9 cm) diameter x 2” (5.08 cm) deep holes approximately 2” (5.08 cm) from the edge on each side of the other channel on the top of the block

3.2 PVC Pipe Modification

We cut several holes into the 4” diameter x 16” long PVC pipe to facilitate driving the concrete anchor screws in and to allow a line to pass through the pipe if needed.

- Cut a length of 4” PVC DWV pipe to 16” (40.6 cm) length

- Find the center of the pipe

- Drill two 2” (5.08 cm) diameter holes at the center point opposing each other 180 deg.

- Rotatepipe90degrees

- Drill two 2” (5.08 cm) holes approximately 2.5” to 3” (6.35 to 7.62 cm) on either side of the center point of the pipe

- Glue on the PVC end cap onto one end of the pipe

- On the opposite end of the pipe:

- Drill two 1/2” (1.27 cm) diameter holes 1” (2.54 cm) from the edge of the pipe

- Oppose the 1/2” holes 180 deg. from each other

- We aligned these to the center 2” holes above

- Oppose the 1/2” holes 180 deg. from each other

- Drill two 1/2” (1.27 cm) diameter holes 1” (2.54 cm) from the edge of the pipe

3.3 Assembly of the Anchor Block

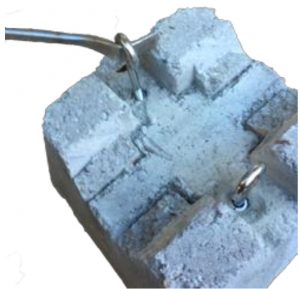

It is easier to install the eyebolts before we attach the 4” PVC pipe to the anchor block (Figure 41).

- Insert a 5/16” thread concrete anchor/lag shield into the hole

- With force, slowly twist in a 5/16” x 4” length stainless steel eye bolt into the lag shield

- Use the cold chisel (or a screwdriver) to continue to screw in the eye bolt approximately 2” (5.04 cm) deep into the lag shield (Figure 41).

Now we can install the pipe:

- Center the 4” PVC Pipe on the block in the newly cut wide channel

- Using a 3/16” (0.47625 cm) concrete drill bit on a drill and through the 2” (5.08 cm) holes in the pipe:

- Drill two pilot holes through the pipe and into the block to mark the locations of the pilot holes on the block

- Remove the pipe

- Continue to drill each these holes approximately 3” (7.62 cm) deep into the block

- Replace the pipe on the block

- The holes in the PVC pipe should align with the holes in the block. If they do not, you can easily re-drill new holes in the PVC as needed

- Drill two pilot holes through the pipe and into the block to mark the locations of the pilot holes on the block

- Place a 1/4” stainless steel fender washer over each of the anchor screws

- Using a drill with 5/16” driver:

- Drive the screw and washer combo through the pipe holes and into the pilot holes in the concrete anchor block

- DO NOT OVERDRIVE / OVERTIGHTEN THE ANCHOR SCREWS